A Photo Essay on the Nitromethane Al/Hgby Dr. GonzoJust the other day, I received a most interesting package in the mail from one of my clients, who we shall call Raoul Duke. It seems that this deviant individual engaged in some organic chemistry earlier this month, and had taken notes and pictures. Incriminating, to say the least, but I am his attorney, after all, and attorney-client privilege is a powerful thing. I have decided to sanitize his notes and pictures so that they cannot be traced back to the real "Raoul Duke", and I've sent the results to Rhodium so all of you bees out there can get a good look at this revolutionary process.

(Raoul's voice) I had some MDP-2-P lying around in the freezer that I'd made in late November, and I really wanted to get rid of it for two reasons: I didn't want it go bad, and I really didn't like having a List I precursor sitting in my freezer. I'd always had some problems doing the Al/Hg with methylamine so I decided to give the nitromethane Al/Hg a whirl. Methyl Man seemed proud of his variation, recently posted on the Hive, so I chose his parameters for the reaction. I have to begin by saying that this is a killer reaction. Methyl Man's pride is totally justified. My yields were awesome and the purity was excellent. I did the whole reaction, with crystallization, in the span of an evening. The reduction ran hot but was completely under control, easily stirred, fast, and simple to work up. I set up a two-liter flat-bottom three-neck flask, and plugged one of the necks. I arranged to have an ordinary condenser in the center hole. The apparatus was placed on my stirrer/hotplate. I started cutting Reynolds Heavy Duty aluminum foil into about 1" squares, to make a total of 27.5g. You just have no idea how much foil is 27.5g until you actually start cutting it up. It must have taken nearly half an hour, and it seriously dulled my scissors. I put 5g batches into a small Braun coffee grinder and ground the foil for 8-10 seconds. The foil doesn't really get "ground", but as Methyl Man says, it gets all balled up into little globs. This worked amazingly well. It may sound weird to put your foil in a coffee grinder, but this is without question a breakthrough in the preparation of aluminum for the Al/Hg.

The foil balls were dumped in the flask. Next, 400mg of HgCl2 was dissolved in 750 mL of lab grade MeOH. While this was being done, 25g of MDP-2-P and 20g of ACS nitromethane were mixed in a dropping funnel with a bit (probably about 25 mL) of MeOH. The MDP-2-P was three months old and had been stored in the freezer. It had been distilled originally, still smelled good and was a medium-light green color. The dropping funnel was put on a side neck on the flask.

When the MeOH was ready (all HgCl2 dissolved), it was also dumped in the flask and the condenser was put in place. As Methyl Man instructed, it was stirred for 5-10 seconds every minute or so. In less than 10 minutes, faint bubbling was visible, the solution was gray, and the aluminum was distinctly less shiny. Some pieces had started to float.

Ice water was started flowing through the condenser. About 4 pounds of ice in 2.5 gallons of water was used, in a 5 gallon paint bucket. The valve on the dropping funnel was opened so that the mix started dripping at around one drop per second. About every minute, I turned on the stirrer for about 5 seconds. After just a few minutes, the flask started to heat up, and I started stirring continuously. At this point the mix had a very distinct steel blue-gray color, like Methyl Man describes.

Eventually the reaction heated itself up to an impressive reflux, and MeOH was flowing nearly continuously from the condenser. I had to adjust the drip speed from time to time (one per second was a little too slow) and I finished the addition after 42 minutes. During the peak of the reaction, I watched what was going on very closely, but I really didn't need to do anything at all except make sure that the addition was going at a rate that would make the whole thing take 40-45 minutes. Everything else took care of itself.

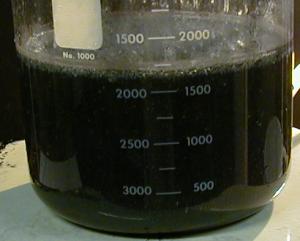

By the time I had a few milliliters of MDP-2-P mix left to go, the reaction was already starting to slow down, though there were still some small aluminum flakes visible. This is exactly in line with Methyl Man's instructions. The mix was starting to get very viscous, so I added another 50-75 mL of MeOH down the condenser which greatly improved things. I then left for about an hour to let the reaction finish itself. When I got back things had cooled considerably and the mix was mostly an amorphous gray with just the tiniest flecks of white mixed in. I mixed 700 mL of water and 262g of NaOH in a beaker. While this was cooling, I dumped the contents of the reaction flask into a 4000 mL beaker. A bit more (maybe 50 mL) MeOH in the reaction flask easily loosened the remaining sludge, and this was dumped into the beaker too. Then the NaOH solution was poured into the 4000 mL beaker with the sludge.

A 3" stirbar was put in the beaker and it was thoroughly stirred. The formerly gray sludge turned darker, and the NaOH started reacting with the remaining aluminum, making a foamy, smelly mess in the beaker. It warmed up slightly but not appreciably. This was left to stir slowly for about an hour, at which time almost all the bubbling was done and the foaming had decreased. I do not own a gigantic sep funnel, so I decided to extract the mix directly in the beaker. This actually works really well and may be easier than dealing with a sep funnel. 500 mL of toluene was dumped in the beaker, and the stirrer was turned on very high for several minutes. This mixed the two phases well. Over the next 15 minutes or so, the toluene separated out to the top.

I was worried, because the toluene had virtually no color to it. I would expect there to be some remaining MDP-2-P with its slight color, or for some reaction impurities to give a color too. But this was slightly milky white. Toluene is kina hard for me to get, so next time I plan to try xylene instead. I suspect this will work fine. Most of the toluene was poured off the top. About 100 mL was left, because it became difficult to get the toluene off without some of the water/sludge layer also pouring out. Another 250 mL of toluene was dumped in the beaker and thoroughly mixed. This next extraction was also poured off, this time with a bit of the sludge layer, and put in the sep funnel. There was probably no more than about 15 mL of toluene left floating on the sludge in the beaker when I was done. Now it was easy to drain off the sludge layer in the sep funnel, leaving only toluene. The first toluene extraction was then added to the sep funnel.

The toluene was washed twice with saturated sodium bicarbonate, once with saturated NaCl, and once with water. All of the washes were quite clean, and the toluene was looking even cleaner than before. The toluene was drained into a washed, acetone-rinsed, thoroughly dried beaker with about 35g anhydrous MgSO4. This was left for about 25 minutes and stirred with a spatula two or three times. It was then filtered into a new beaker (also super dry), and the MgSO4 in the filter washed with a little new toluene. A standard NaCl/H2SO4 generator for HCl gas was set up, with a fractionating column packed with CaCl2 (Damp-Rid from Home Depot) as a drying tube. A gas dispersion tube with a porous glass disc was attached to the drying tube, and the H2SO4 was started dripping. Gas began to come out of the dispersion tube, which I immersed in the toluene filtrate. Absolutely nothing had happened after several minutes and I was convinced I had totally fucked up. Then a wisp here and there of white material started to appear, and within 30 seconds there were giant clouds of puffy MDMA HCl cascading out of solution. I nearly shit my pants.

I would recommend against using a gas dispersion tube, since it seems to clog up with crystals and generate serious backpressure in the HCl generator. At one point, a glass stopper popped right off the apparatus, there was so much pressure. Just use a glass tube to get your HCl into the toluene. The solution was so cloudy that I couldn't tell if any more crystals were precipitating, so I decided to stop. The beaker was covered and put in the freezer for half an hour. When cold, it was filtered with vacuum in a Buchner, then dried on a mirror under a light bulb (for heat) and weighed. There was a total of 8.26 g. Then I set up to gas the toluene again. And lo and behold there was another massive precipitation of crystals. The toluene was chilled and filtered and the filtrate dried, yielding another 4.72 g! Set up to gas again... it just keeps on coming. I give the crystals some time to settle, and now there really doesn't seem to be any more coming out of solution. Chill, filter and dry. This time there was 6.61 g more! Even though the crystals had a slight (and very pleasing) root beer odor, I decided against recrystallizing because the crystals were blindingly bright white and obviously of good purity.

Total yield: 19.6 grams of MDMA HCl - from 25 grams of ketone !! Bioassay: Unqualified success. I have to say that Methyl Man has scored a serious winner with this procedure, especially with the management of the amalgam. He's figured out how to make it easy to stir, how to make it run at the right rate, and how to work it up way more easily than I've ever seen. And you don't even need to make methylamine! This, in conjunction with Bright Star's writeup of the ketone synthesis and purification, makes for the most straightforward MDMA synthesis the Hive has ever seen. Reference: Methyl Man's Reductive Amination |